Applications

Textile

In addition to a wide range of standard axial and centrifugal fans that meet our customers’ needs, we provide customized solutions for the most critical and demanding applications, thanks to our know-how.

Depending on the application, our fans can be made of special materials by choosing from a variety of protective coatings or finishes to protect against surface corrosion. For applications where fans must manage process flow under particular conditions, we have developed safe and reliable solutions for high temperatures and continuous trim transport, available in hardened steel to prevent surface wear.

Our products are used in many different processes and applications, such as in steam extraction on drying tunnels, pneumatic systems, chemical treatments and conditioning of trimmings, air extraction, collection of dust and shredded materials, raw material treatment, combustion air for burners, continuous cleaning of machinery and filters. Many of our fans are also used for ventilation of workplaces and technical rooms.

Milling Food

With our wide range of production, we have been designing solutions for the food and milling industry for more than 50 years. All our standard production range is created to meet the needs of our customers.

Within our organization we have a division that works closely with our customers for developing cutting-edge solutions specifically designed and adapted to special needs. This division steps in when customers ask us to adjust dimensions to their machines or where specific materials are required. The fans used in the food industry must meet special requirements in terms of hygiene; our products can be supplied in AISI 304, AISI 316L or AISI 316Ti stainless steel with surface finishing treatments, such as shot peening. Our fans can also be equipped with a range of accessories specifically designed for the food industry.

The reliability of our products is appreciated by major plant manufacturers in the wheat-processing industry, flour production, as well as all drying and recirculation processes for wheat, pasta, bread, biscuits, snacks, cereals, etc. We also offer solutions for coffee roasting, refrigeration, egg and dairy processing plants. In addition, we can supply fans for animal feed and food production facilities.

Asphalt, Cement and Brickworks

Our fans are successfully applied in burners, drying and filtration systems. Customized burner solutions are designed in conjunction with our customers.

Customized burner solutions are designed in conjunction with our customers, by considering the space available and the aesthetic shapes required by the impeller casing.

For burners, flanged motors are normally used, so reinforced casing solutions are needed in order to ensure reliability and long service life. Drying is a key process, and depending on the characteristics of the raw materials, it may be necessary to use impellers made from materials with high hardness and abrasion resistance. Most of our fans serving this sector enhance the filtration system and are appreciated by the leading manufacturers of these systems. High temperatures in combination with acidic atmospheres and possible condensation risks may sometimes require the use of special materials such as COR-TEN or stainless steel. With the aim of improving surface resistance and avoiding corrosion phenomena, dedicated painting cycles are available.

Our fans are also used at cement and lime production facilities. This kind of plant use combustion air, which when heated must be recirculated, extracted and then filtered. Our products can be used in all the processes just mentioned. In addition, for lime production facilities, our fans are utilised in hydration plants and high-temperature gas extraction plants that can reach up to 450°C.

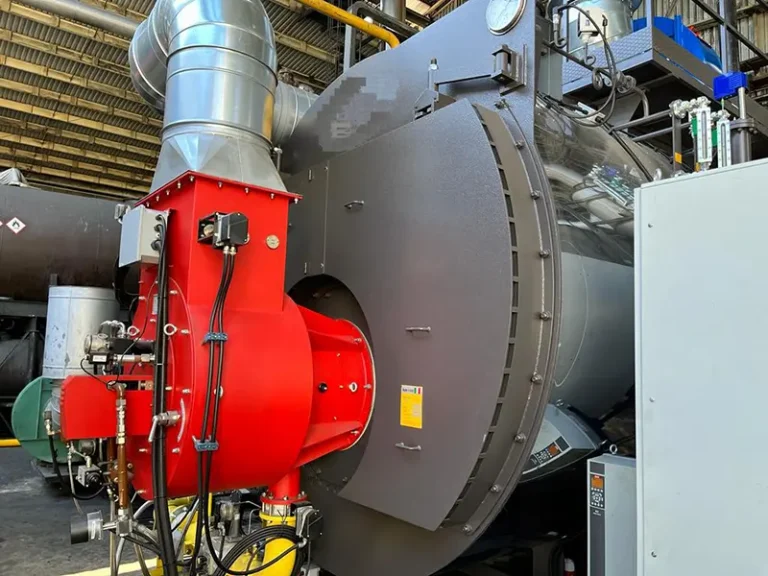

Industrial Burners

Industrial burners are normally fed by combustion air supplied by a fan. With our wide range of production, we can meet all needs related to the supply of these products.

Our customers can be supplied with burners for the fields of agriculture, food, paper and pulp production, cement and asphalt, iron and steel industry, aluminium foundries, Oil & Gas, etc. Fans can be designed according to specific dimensional characteristics and be suitable for integration into the burner itself or supplied separately from the burner making the solution more versatile and adaptable.

Paper and Non-woven Fabric

When heavy construction due to process conditions, long-lasting reliability, and energy-saving solutions become increasingly crucial, SIA’s technology is the answer you are looking for.

A wide range of well-proven solutions, based on 35 years of experience, suits any requirement. High quality standards, proven resilience, and state-of-the-art design criteria improve customers’ investments in terms of durability and less downtime.

Our products can be found in various processes and applications in paper processing such as drying hoods, heat recovery systems, filtration of dust, fumes and oil mists, and combustion air for burners; in the non-woven fabric industry, for extraction of hot air from tunnel and drum ovens, pre-mixing and air carding; in pulp processing machines for pneumatic conveying, or supporting the forming drum and collectors of dust and shredded material.

Ceramics and Bricks

In the production process of structural ceramics (bricks, shingles, tiles, etc.), fans play a key role in the drying and firing processes of materials and in combustion systems.

Both centrifugal and axial fans are frequently used in the kiln and dryer.

The most commonly-used centrifugal fans are transmission and single inlet fans, which are suitable for moving large volumes of air. Very high airflow capacities of up to 200,000 m3/h can be achieved with them while maintaining the head levels needed in these systems, around 800-1200 Pascal. Our products can process airflows with temperatures up to 450°C. For materials generated from particularly aggressive clays, fans can be supplied, totally or partially, with corrosion-resistant materials.

Axial fans are used to move large amounts of air to where the required heads are lower. These are compact solutions that take up little space and can be used either vertically or horizontally, thus optimizing available space. Fans with belt drive are the most widely used, since they keep the electric motor separate from the airflow, being suitable for working with air temperatures up to 80°C. When the fluid temperature exceeds this threshold, the choice shifts to products that must protect critical transmission components such as belts and bearings from the heat. Solutions with bifurcated fans, or fans with forced cooling systems allow for working temperatures of up to 180°C in continuous operation.

Filtration and Dedusting

SIA fans are particularly suitable for the filtration and dedusting industry. Our fans have a sturdy structure but at the same time are sufficiently compact and modular.

Our fans have a sturdy, compact, and modular structure making them an excellent solution that can be adapted to different types of plants without unnecessarily burdening their support structures.

This keeps the inherent vibration level of the static and rotating components of the fan very low and, consequently, the level of vibration transmitted to the structures. In addition to standard configurations, there are specific solutions developed to allow vertical axis mounting up to sizes and powers not permitted by traditional designs.

The diversity of available impeller profiles makes SIA fans suitable for any zone of the plant. Impellers with forward blades are generally used upstream filters in zones with large amounts of dust in the air, while those with reverse blades are appropriate for working downstream filters with clean or slightly dusty air while maintaining very high levels of efficiency. Fans with open impellers, either forward or straight blades, are used in systems that require the conveyance of different kinds of materials in suspension.

There is a very wide range of products with certification to work in explosion-prone zones in compliance with the European ATEX Directive 2014/34/EU. Available solutions include certification of fans and related electrical equipment under different categories that establish how products should be designed and constructed, based on different parameters such as the intensity and duration of the explosion risk or its possible origin (hazards originating from dust or gas).

It is common for filtration and dedusting plants to have important and severe restrictions imposed on the noise emissions from their operation. In this field, SIA fans help keep emissions below the levels specified by the most stringent regulations. To achieve this goal, product design is carried out by considering aspects that contribute to reducing the noise characteristics of rotating machines by acting on the loudness of the sound generated by them.

Oil & Gas

For the last 20 years, we have been supporting the steady growth of the Oil & Gas business, along with the leading players involved in this sector. We supply not only a full range of centrifugal and axial fans but also customized solutions.

In addition to our full range of centrifugal and axial fans complying with applicable API standards, we provide customized solutions for the most critical and demanding applications, both according to the specifications of the installation firm and the end user.

With expertise gained over a long period of time and a flexible approach, our engineering can provide specific features regarding general design, construction materials and surface protection materials, spark-proof versions for explosive atmospheres, certified welding processes and tests, and documentation and certificates according to international guidelines and local regulations.

Our products are utilised in many different processes and applications, such as in cabinet cooling, exhaust shaft and frame of turbo-gas generators, combustion air for flare burners, exhaust gas and vapour extraction, cooling towers, and catalyst cracking reduction for gas treatment units.